Laser Crystal

Using high-quality laser rods, it has the characteristics of high gain, low laser threshold, high laser power, beautiful welding points, high energy, and good thermal conductivity and thermal shock.

The weiding effect is clear. Men and women all can work,high efficiency, starting up can use directly, welding speed is 5 times than the traditional technology.

Adopt 8 super laser power and imported IGBT bipolar transistors,to make the power supply pulse xenon lamp current more constant,high-frequency continuous welding.

Independent high-definition touch control screen,control pulse current, the setting parameters will be airomatically saved.

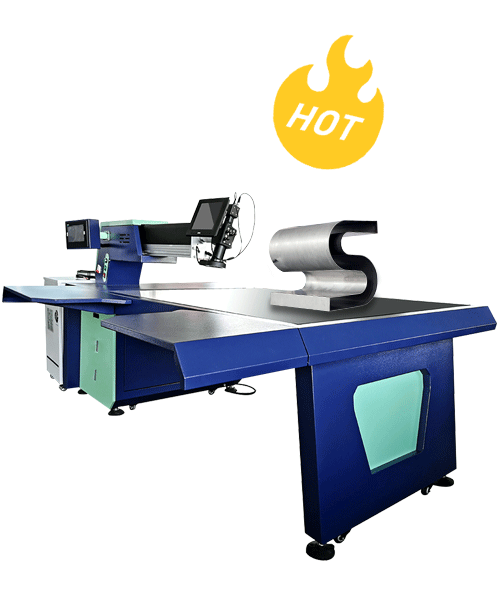

The letter laser welding machine can seamlessly weld stainless steel, galvanized iron, flat steel sheet, titanium, and other metals. It can also be used for welding microelectronic parts, precision parts, digital parts, optical fiber connectors, and medical equipment.

The laser welding machine has a high degree of automation and a simple welding process. The non-contact operation method can meet the requirements of cleanliness and environmental protection. The use of a laser welding machine can achieve no noise, no pollution, no radiation, 24 hours of continuous work, which can improve the efficiency of processing parts.

Laser welding machine requires high precision of welded parts, so we can send the parts that have been processed by channel letter bending machine to laser welding machine for welding work.

Get A Quote on WhatsApp

Using high-quality laser rods, it has the characteristics of high gain, low laser threshold, high laser power, beautiful welding points, high energy, and good thermal conductivity and thermal shock.

The excellent cooling system can provide a long working environment for the whole machine. The cooling system consists of a high-power constant-temperature refrigerating water tank, with automatic constant temperature function for heating and cooling, and high control accuracy. The German EBM electronic fan is used as the condensing part, with large air volume, low noise, and filtering device, which can effectively filter dirt and impurities in the water.

Specially-made moving light path, telescopic freely, extended focus lens F=150MM, can achieve multiple zooms, better focus to achieve excellent welding effect.

DEFY laser welding machine manufacturer can customize the production of fiber laser welding machine, tell us your needs, and provide you with professional customized services.

| Model | DF-W300 | DF-W300D |

| Max. power | 300W | 300W |

| Laser wavelength | 1064nm | 1064nm |

| Concentrating cavity emitter | imported ceramic concentrating cavity | imported ceramic concentrating cavity |

| Laser type | Nd: YAG | Nd: YAG |

| Single pulse max. energy | 90J | 90J |

| Spot size | 0.2-2mm | 0.2-3mm |

| Cooling system | 1.2P integrated | 1.2P integrated |

| Welding depth | 0.1-2.6mm | 0.1-2.6mm |

| Observation system | optional CCD plus red light | optional CCD plus red light |

| Laser up and down stroke | 200mm | 200mm |

| Total power | ≤6kw | ≤6kw |

| Electricity demand | 220v ±10%/50HZ/40A | 220v ±10%/50HZ/40A |

| Work table | 1200*2050mm, or customized | 1200*2050mm, or customized |

| Boom system | 1200mm(W130mm*H170mm) | 1200mm(W130mm*H170mm) |

| Dimension | main machine:700*720*1030mm | main machine:700*720*1030mm |

| cooling part:520*445*780mm | cooling part:520*445*780mm |

The handheld laser cleaner can achieve cleaning effects on objects without grinding, non-contact, and no thermal effects.

The handheld laser welding machine has the characteristics of high welding efficiency, cost-saving, convenient movement.

Laser engraving machine is an advanced equipment that uses a laser to engrave materials that need to be engraved.

As provider of advanced laser equipment, Zhengzhou Defy has nearly ten years of production experience, exported to more than 80 countries around the world, and provided professional project guidance for more than 8,000 customers. We has strict and effective quality management system, one-stop pre-sales, sales and after-sales services system and professional project management team.

▶ The welding depth of the 200w laser welding machine is 0.5mm, which can realize spot welding and penetration welding.

▶ If you need continuous welding, you need to choose a 250w or 300w fiber laser welding machine.

▶ The greater the power of the laser welding machine, the greater the welding depth.

We will send all original documents to you by DHL after sea shipment or together with the machine by air, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

1. Optical characteristics: spot size (laser rod diameter, fiber diameter, and type, output head parameters), focal plane height, depth of field, spot position, spot angle of incidence;

2. Control characteristics: feedback control mode, choice of power waveform.

After the fiber laser welding machine has been working continuously for two weeks or stopped for a period of time, the components in the optical path such as YAG rod, dielectric film, and lens protection glass should be checked before starting to make sure that the optical components are free from dust pollution and mildew If there are any abnormal phenomena, they should be dealt with in time to ensure that the optical components will not be damaged under strong laser irradiation. (If the use environment of the equipment is relatively clean, the equipment can be kept in normal operation for more than 1 month.)

For standard machines, it would be 7-10 days; For customized machines according to clients’ specific requirements, it would be a little longer, about 15 to 30 days.

The warranty is two years. During the warranty, in case of any problem for the machine, we will provide the parts free of charge. After the warranty, we still provide whole lifetime service.