Automated Welding

The integrated imported chips have created a high degree of automation of the laser welding machine, a simple welding process, and reduced working time and operation difficulty.

Use laser infrared rays to achieve precise positioning, making the weld beautiful and not offset.

In order to adapt to various welding products, this laser welding machine is adapted to various welding heads, making welding more convenient.

Imported chips are used to increase chip reliability, reduce chip area, and reduce costs.

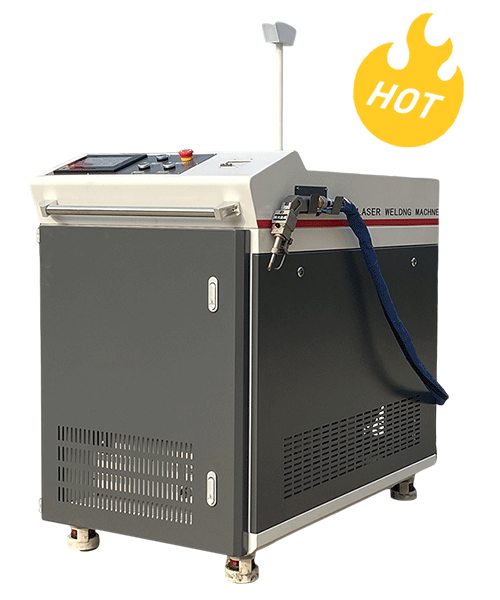

In order to facilitate the ease of use of the fiber laser welder machine, we design the laser welding machine as a handheld laser welding machine, which can weld the weld from all angles. And its main body is movable, it can be used anywhere only by extending the wire, which makes the laser welding machine get rid of the limitation of the use area.

The fiber laser hand-held welding machine has high welding efficiency, and the hand-held laser welding speed is fast, which is more than twice that of argon arc welding. It can easily double production efficiency on the basis of saving 2 welding workers.

Hand-held laser welding belongs to hot fusion welding. Compared with traditional welding, laser welding has a higher energy density and can achieve better welding results. It can be welded instantly, without scars and deformation.

Laser welding saves the welding seam grinding process required by traditional welding and greatly reduces the working time. And fiber laser welding can also achieve long-term continuous welding.

Get A Quote on Email

The integrated imported chips have created a high degree of automation of the laser welding machine, a simple welding process, and reduced working time and operation difficulty.

The handheld laser welding machine is adapted to different laser welding heads. According to different products and welding seams, choosing the right welding head can achieve small welding seams, large welding depths, good welding effects, and beautiful finished products.

The 1000W high-power handheld laser welding machine can focus the beam and reduce the spot size. In addition, the laser frequency becomes faster, which can increase the speed of laser welding.

Hand-held laser welding does not require a fixed-point workstation, is free and flexible, has a wide range of reach, and can become a worksite anywhere.

| Laser Parameters | Water Cooling Parameters | Welding Head Parameters | |||

| Laser Power | 1000W | Cooling Capacity | 5.2KW | Power Range | 0-3000W |

| Laser Wavelength | 1080 | The Tank Volume | 24L | Laser Wavelength | 1080nm |

| laser Frequency | 10-2000HZ | Cooling Medium | R22 | Collimated Focal Length | 50MM |

| Infrared Positioning | 0.2mW | Temperature Control Range | 26±1℃ | Focus Focal Length | 120/150MM |

| Fiber Cable Length | 15M | Warning Function | Water level, low temperature, high temperature, overload, etc | Protective Lens | D20X2MM |

| Voltage | 220V 50Hz | Environmental Requirement | 5-45 ℃ temperature; 10-90% humidity | Weight of Handle | 0.6-0.8kg(Ultra light mini) |

The handheld laser cleaner can achieve cleaning effects on objects without grinding, non-contact, and no thermal effects.

The letter bending machine can realize automatic feeding, automatic grooving, automatic bending, and other processes, and easily realize material processing.

Laser welding machine, also often called a laser welding machine or laser welding machine is a machine used for laser material processing.

Laser engraving machine is an advanced equipment that uses a laser to engrave materials that need to be engraved.

As provider of advanced laser equipment, Zhengzhou Defy has nearly ten years of production experience, exported to more than 80 countries around the world, and provided professional project guidance for more than 8,000 customers. We has strict and effective quality management system, one-stop pre-sales, sales and after-sales services system and professional project management team.

The main factors affecting the welding speed of fiber laser welding machines are divided into internal factors and external factors.

▶ The internal factors are mainly laser frequency, laser spot mode, and beam divergence angle, laser power, reasonable optical shaping, and auxiliary gas and material during processing.

▶ The external factors are mainly welding density, welding width, welding depth, and laser spot size.

We will send all original documents to you by DHL after sea shipment or together with the machine by air, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

▶ There are no consumables for welding, which reduces the cost of materials in production and processing.

▶ Fast welding speed can save time and cost.

▶ The welding effect is good and the grinding cost can be saved.

▶ The operation is simple, saving the labor cost of hiring professionals.

Mobile phone fiber laser welding machines are widely used in kitchens, household appliances, advertising, molds, stainless steel doors and windows, handicrafts, household goods, furniture, auto parts, and many other industries.

For standard machines, it would be 7-10 days; For customized machines according to clients’ specific requirements, it would be a little longer, about 15 to 30 days.

The warranty is two years. During the warranty, in case of any problem for the machine, we will provide the parts free of charge. After the warranty, we still provide whole lifetime service.